The RAW Modular Training Experience

Posted on | No Comments |

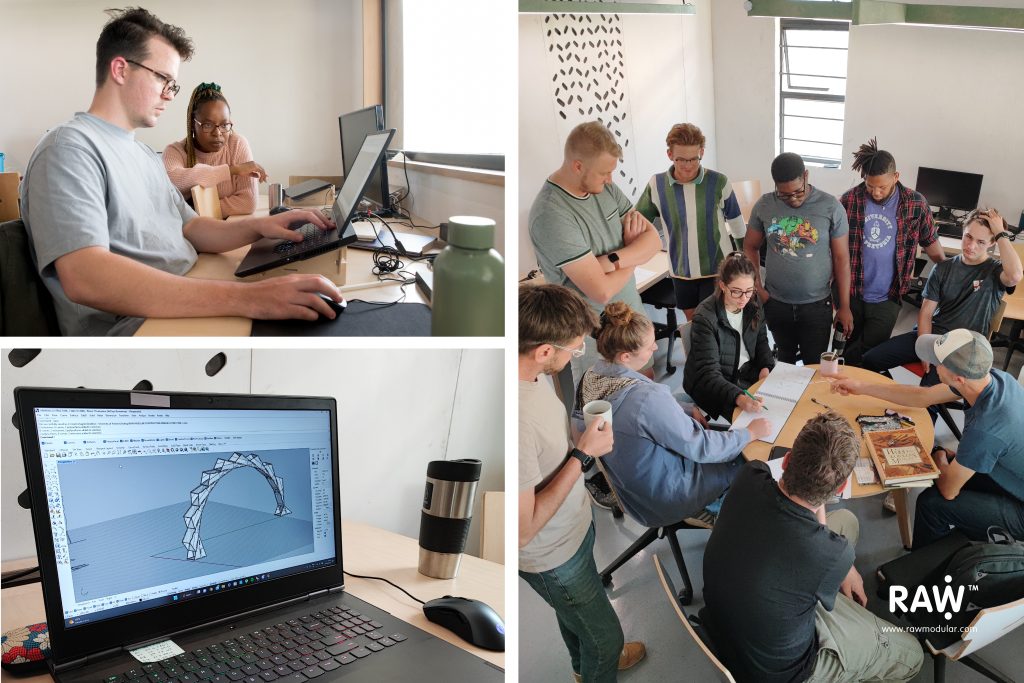

During the week of 23-27 January ‘23, Raw welcomed a group of 15 Architecture students from the University of Pretoria for a Plywood Design and Construction week. The aim of the week was to familiarise the students with the processes around designing and manufacturing with plywood by using contemporary design and machining techniques. This course is envisioned to be the first in a series of training weeks – taking the students from a basic understanding of plywood design and manufacturing to creating parametric systems that aid in the design of multiple-use structures.

The brief asked the students to think of plywood in a structural way, to think of the possibilities of the foot, joint, and column and/or beam of a structural component or structural system, that spans 4 metres and meets the surface on 2 different levels. The students had to ultimately translate their design into CAD and CAM software models, and then into a full-size prototype for testing.

The sky was the limit as the students put pen to paper generating ideas of plywood-grandeur, which then, guided by industry experts – Thinus, Peet and Kyle, were refined into workable designs.

We’d like to thank York Timbers, in association with the University of Pretoria, who set up this programme with the aim to further the timber construction industry, by exposing young students to ways of fabrication and design of structural plywood. This is of course falls perfectly in alignment with Raw’s vision to include an educational training aspect to our offerings through more engagement with universities, and professional training programmes.

Are you part of a company/ university interested in Plywood Design and Construction training? Or perhaps you are a professional struggling to prototype your work efficiently? Let’s get in touch.